In modern production systems, equipment management is shifting from traditional extensive maintenance to refined management. Mechanical equipment maintenance animation, as an emerging technological means, provides innovative solutions for enterprises to achieve refined equipment management through visualization and standardization. This technology not only changes the execution methods of equipment maintenance but also redefines the concepts and standards of equipment management.

Establishment and Implementation of Visualized Maintenance Standards

The foundation of refined equipment management is to establish a comprehensive maintenance standard system. Traditional equipment maintenance often relies on the personal experience and memory of technicians, leading to problems of inconsistent standards and inadequate implementation. Mechanical equipment maintenance animation, through precise 3D demonstrations, transforms abstract maintenance standards into intuitive visual processes, ensuring that every maintenance personnel can accurately understand and execute unified standards.

In practical applications, these visualized standards significantly enhance the standardization of maintenance operations. The practice of Guangdong Topin Intelligent Machinery Technology Co., Ltd. shows that guiding equipment maintenance through maintenance animations not only improves operational efficiency but, more importantly, ensures the stability of maintenance quality. Through animated demonstrations, maintenance personnel can accurately grasp the technical requirements and operational key points of each maintenance step, avoiding operational errors caused by misunderstandings.

Precise Execution of Preventive Maintenance

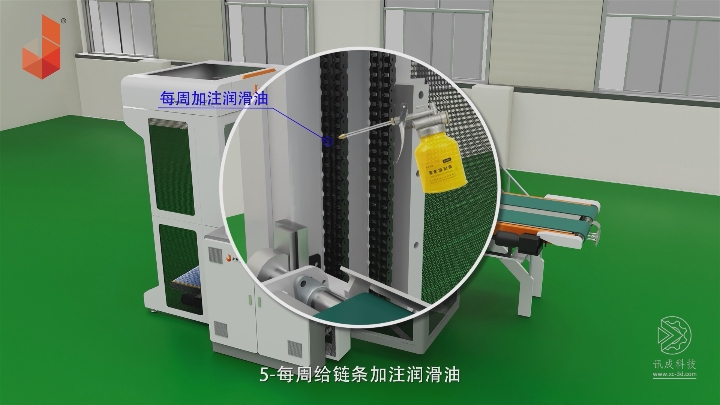

The core of refined equipment management lies in the shift from passive repair to proactive prevention. Mechanical equipment maintenance animation, by demonstrating equipment operating mechanisms and wear patterns, helps management establish scientific preventive maintenance systems. This preventive maintenance not only effectively reduces equipment failure rates but also significantly extends equipment service life.

The case of Shenzhen Wandee Digital Technology Co., Ltd. shows that a preventive maintenance system based on 3D animation has reduced the incidence of sudden equipment failures by over 40%. The animation clearly demonstrates the inspection cycles and maintenance standards for key equipment components, helping management accurately grasp the timing of maintenance. This precise preventive maintenance avoids resource waste from over-maintenance and prevents equipment failures due to under-maintenance.

Digital Control of Maintenance Processes

Mechanical equipment maintenance animation provides technical support for the digital control of maintenance processes. By integrating elements such as maintenance standards, operating procedures, and safety regulations into the animation system, enterprises can establish a comprehensive maintenance management database. This system not only guides on-site operations but also enables the traceability, evaluation, and optimization of maintenance processes.

In actual operation, this digital system demonstrates significant advantages. Maintenance personnel record operational status through the animation system, allowing management to monitor maintenance progress and quality in real-time. This transparent management approach strengthens supervision of the maintenance process and provides data support for continuous improvement. More importantly, digital control makes the evaluation of maintenance quality more objective and accurate.

Systematic Construction of Knowledge Management

Refined equipment management requires the support of a comprehensive knowledge system. Mechanical equipment maintenance animation, by systematizing and standardizing scattered maintenance experiences, builds a knowledge management system that can be continuously accumulated. This system not only preserves existing technical knowledge but also establishes a mechanism for continuous knowledge updating.

The practice of Foshan Jinbing Machinery Co., Ltd. proves this value. The company has accumulated a large number of maintenance cases through maintenance animations, forming an ever-richer library of solutions. When encountering new equipment problems, technicians can quickly search for relevant cases and draw upon the experience of their predecessors. This systematic knowledge management greatly improves the efficiency and quality of problem-solving.

Optimized Allocation of Maintenance Resources

Refined equipment management requires the optimal allocation of maintenance resources. Mechanical equipment maintenance animation, through precise prediction of maintenance needs and evaluation of operation times, provides a reliable basis for resource allocation decisions. Management can scientifically arrange maintenance plans and rationally allocate human resources based on the data provided by the animation system.

This optimized allocation has achieved significant results in practice. On one hand, it avoids the idle waste of maintenance resources; on the other hand, it ensures that critical equipment receives timely maintenance. The experience of Xiamen Sanlei Packaging Materials Co., Ltd. shows that after optimizing resource allocation through the animation system, maintenance costs were reduced by 25%, while equipment availability increased by 15%.

Comprehensive Improvement of Safety Management Level

Safety is the primary consideration for refined equipment management. Mechanical equipment maintenance animation significantly enhances the safety level of maintenance operations by demonstrating safe operating procedures and accident prevention measures. The animation can clearly show the safety key points of each operation step and the consequences of non-compliant operations, a visual warning effect far superior to traditional text descriptions. In practical applications, this safety education method has achieved remarkable results. Maintenance personnel learn through animation, deeply understand the importance of safety regulations, and consciously adhere to them in their work.

Establishment of a Continuous Improvement Mechanism

Mechanical equipment maintenance animation also provides an effective tool for the continuous improvement of equipment management. By recording and analyzing data and cases from the maintenance process, enterprises can continuously identify shortcomings in management and make targeted improvements. This continuous improvement mechanism ensures the ongoing enhancement of equipment management levels.

More importantly, this improvement is systematic and sustainable. Lessons learned from each maintenance case can be preserved in animated form, becoming shared knowledge assets for the organization. This mechanism of continuous accumulation and improvement continuously enhances the company's equipment management capabilities, maintaining a leading position in the industry.

Mechanical equipment maintenance animation provides comprehensive solutions for enterprises to achieve refined equipment management through multiple dimensions such as the establishment of visualized standards, implementation of preventive maintenance, and digital control. This innovative technology not only enhances the efficiency and quality of equipment management but, more importantly, establishes a continuous improvement management mechanism. With the continuous development of technology and deepening applications, mechanical equipment maintenance animation will undoubtedly play an even more significant role in the field of refined equipment management.

Featured FAQs:

Q: How to produce 3D animations related to equipment maintenance?

A: Most mechanical and production plants rely on experienced and qualified electromechanical engineers for equipment maintenance. Equipment maintenance animation can effectively solve this problem.

1- It is recommended to first produce animations for common equipment failure points (including mechanical and electrical);

2- Record and document on-site maintenance to accumulate material for animation production;

3- Quantity: It is recommended to produce around 10-15 mechanical maintenance animations and 5-8 electrical maintenance animations for large equipment in the early stage; for medium and small equipment, around 6-8 mechanical maintenance animations and 3-5 electrical maintenance animations;

4- Equipment maintenance animation is a process of continuous accumulation and optimization with a relatively long production cycle. Project contact personnel should be relatively stable.

Q: What sections does Xuncheng animation video production include?

A: Animation video production includes the following three categories:

Promotional: Including product promotion, corporate promotion, etc.

Technical: Including equipment operation, equipment maintenance, equipment repair, consumable replacement, equipment assembly, equipment safety, etc.

Customized: Including exhibition videos, investment promotion videos, dinner warm-up videos, etc.

Q: Will equipment use animations expose sensitive structures of the equipment?

A: No.

Equipment use animations demonstrate the content of traditional paper operation manuals in the form of animated videos (e.g., in printing machines, the paper feeding unit mainly explains how to adjust baffles and guides, and how to feed paper; the printing unit mainly explains how to ink, change plates, and adjust printing pressure, which do not involve sensitive equipment structures). Mechanical factories can also delete or deform sensitive equipment structures when providing equipment models.

The control always remains with the mechanical factory.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, serving clients ranging from startup teams, overseas clients, listed companies, and foreign-funded enterprises. Focused on providing 3D animation creation services for mechanical equipment, high-tech, software development, foreign trade companies, etc. Offering one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

Provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises.

Whether at exhibition sites or visiting clients; whether expanding into overseas markets or improving after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented in stunning 3D animations. This not only brings a unique visual experience to clients but also quickly captivates them.